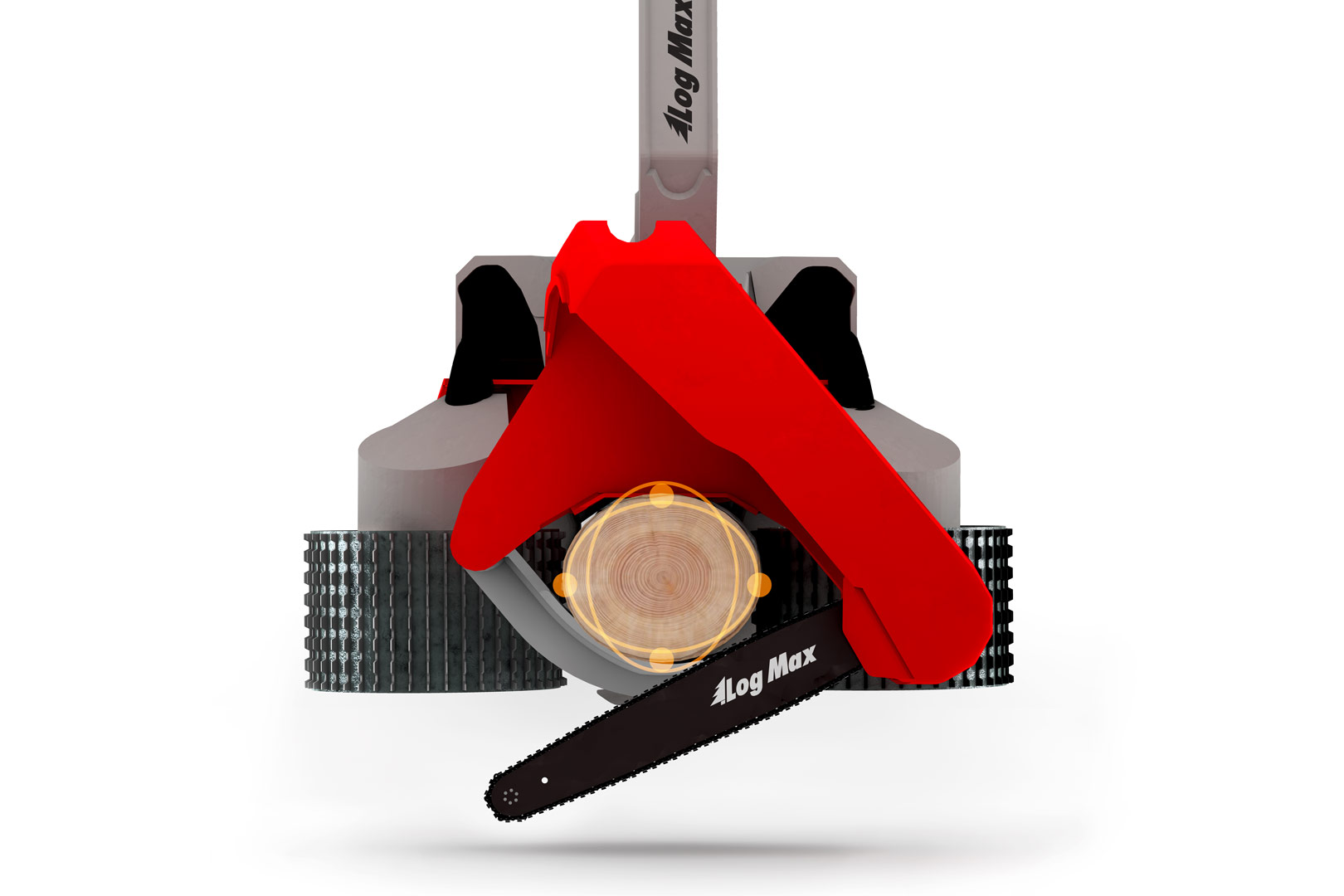

FOUR-POINT MEASUREMENT

Accurate measurements using four points

EXACT VOLUME CALCULATIONS

We are the only supplier on the market to offer customers diameter measurements based on four measurement points. This ensures reliable volume calculations and bucking with the best possible measurement results, even with extremely oval trees.

How does diameter measurement work?

Measurements are made using four points: two opposite each other in the feed rollers, one in the lower delimbing knife, which consists of a sensor, and a baseline in the frame.

The sensor's job is to calliper the stem every decimetre and then forward the reading to the control system. The control system combines this reading with the values provided by the feed rollers. This enables the system to present extremely good measurement results, even with oval trees, based on four measurement points.

Four-point measurement is available for Log Max heads in the 4000, 5000, 6000 and 7000 series.

HOW SHOULD YOU MEASURE?

To optimise the functionality of your Log Max head, it is important that you calliper and calibrate correctly. A head that is correctly set up delivers not only better measurements, but also smoother operation.

Measure at a 90° angle

You measure the diameter twice. First where the feed rollers passed the stem, and then 90° from there, that is, where the lower delimbing knife passed.

Since the measurement points on the head are found here, it is important that you measure the same way.

For a more detailed description and other important points to keep in mind, we recommend that you download the brochure "MEASUREMENT INSTRUCTIONS", which can be found further down the page.

Important to remember!

NEVER AN INCREASING DIAMETER

If a stem is registered in the system with an increasing diameter, the computer will automatically filter out the increase and instead create a flat area in the stem profile. Accordingly, always look for the smallest diameter when using the calliper.

UPDATED CALLIPER

To be able to calibrate the four-point measurement system, you need a computer calliper that supports this function. Support was introduced in Haglöf's version 6.9.

GOOD CONDITION IMPORTANT

To ensure accurate measurement results, it is important that the measuring instruments are in good condition. Check the condition of both the measuring wheel and the computer calliper, for example.

Useful brochure