Log Max 7000Twin is a robust head that is built to withstand a little more. It is powerful and specially adapted to be mounted at tracked carriers. It has double lower delimbing knives for extra delimbing coverage near the root end.

FIVE DELIMBING KNIVES

The head has five delimbing knives ideal when harvesting low-branched spruce.

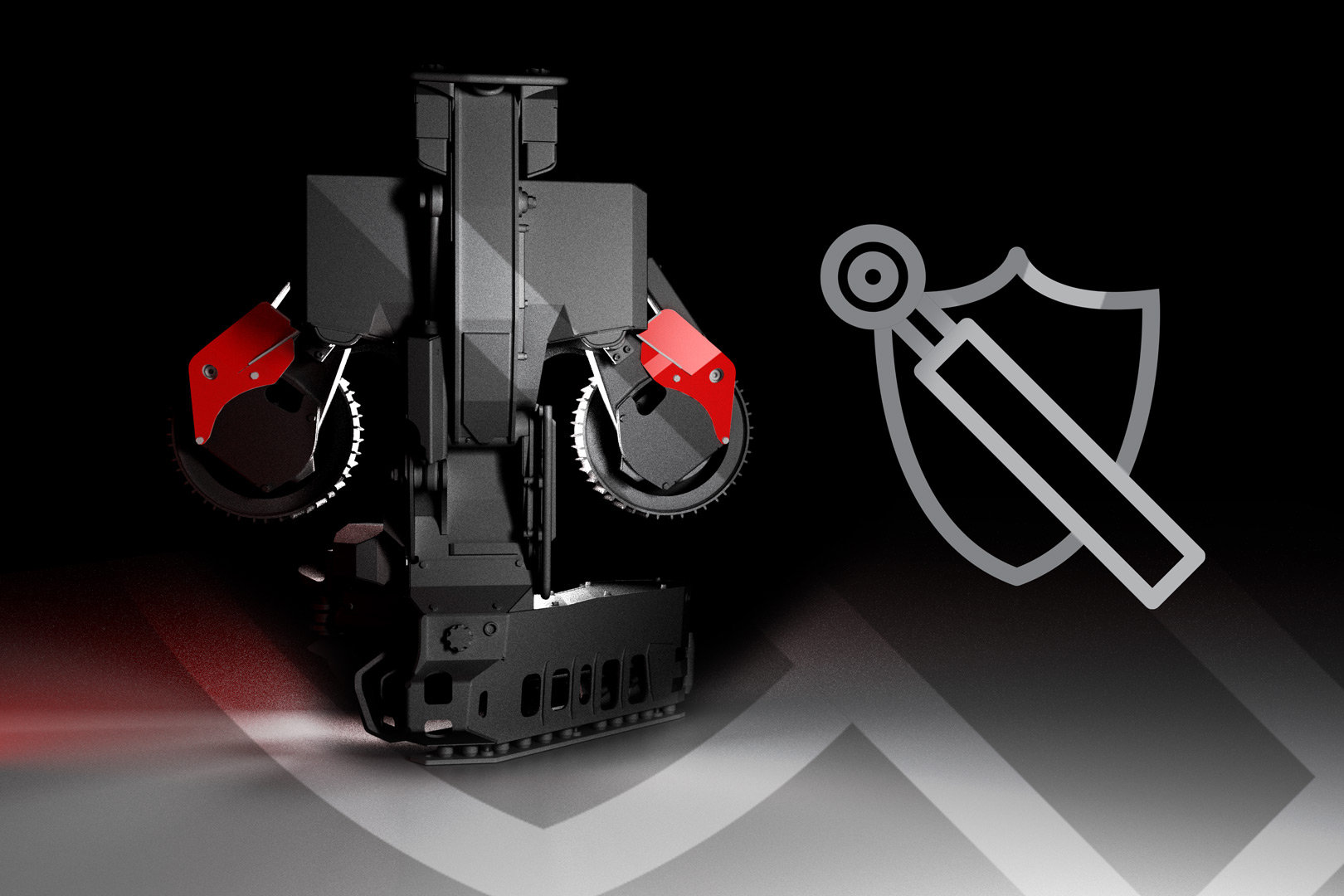

EXTRA DURABLE

The Heavy Duty-Kit protects cylinders and hoses from incoming twigs and branches.

CAST FELLING LINK

The head has a cast felling link that withstands the harshest of conditions.

Weight

1892 KG

Highest productivity

16 - 50 CM

Between feed rollers

1.3 - 71.3 CM

Max cutting diameter

75 CM

Assets diameter

52.6 CM

What do customers say?

Andrew Heatley - Australia

This head is a great match for my Tigercat tracked carrier. The variable motors are just amazing and have loads of torque.

Darwin, Timbertec Forestal - Spain

7000Twin is a very reliable, practical and robust head! I like the five knives but also the exact measuring system. I would recommend others buy the head as it is very reliable and easy to maintain and serve!

FEATURES

What makes Log Max 7000Twin your best choice

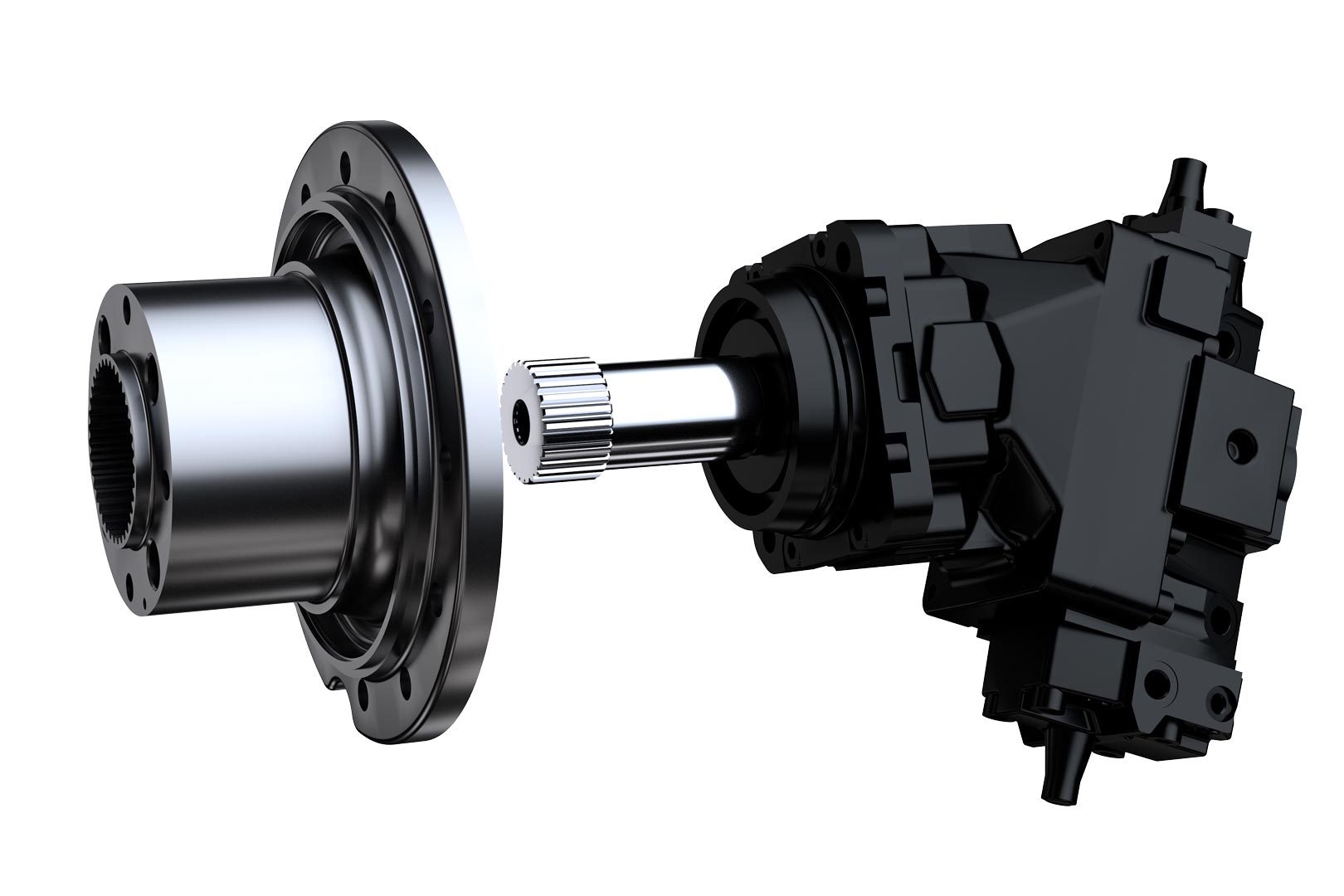

Smart feed roller motor

The feed roller motors have a variable displacement ranging between 830 and 1320 cc, this provides an automatic, dynamic adjustment of the feed speed and torque regardless of the log diameter.

If you work with small trees, you get a high feeding speed and when you work with larger diameter trees, higher torque is prioritized. This functionality provides a great user experience and also improves fuel consumption.

Twin delimbing knives

Thanks to the double lower delimbing knives that characterize the head, the head works very efficiently in forests with coarse, low-growing branches.

Cast felling link

The felling link is cast in one piece to maximize its strength and durability. The cast link is standard on the XT, Twin, and E6 heads. This is a more robust construction, great for heads mounted to tracked carriers or excavators working in tough conditions.

TECHNOLOGY

Unique technologies for your Log Max head

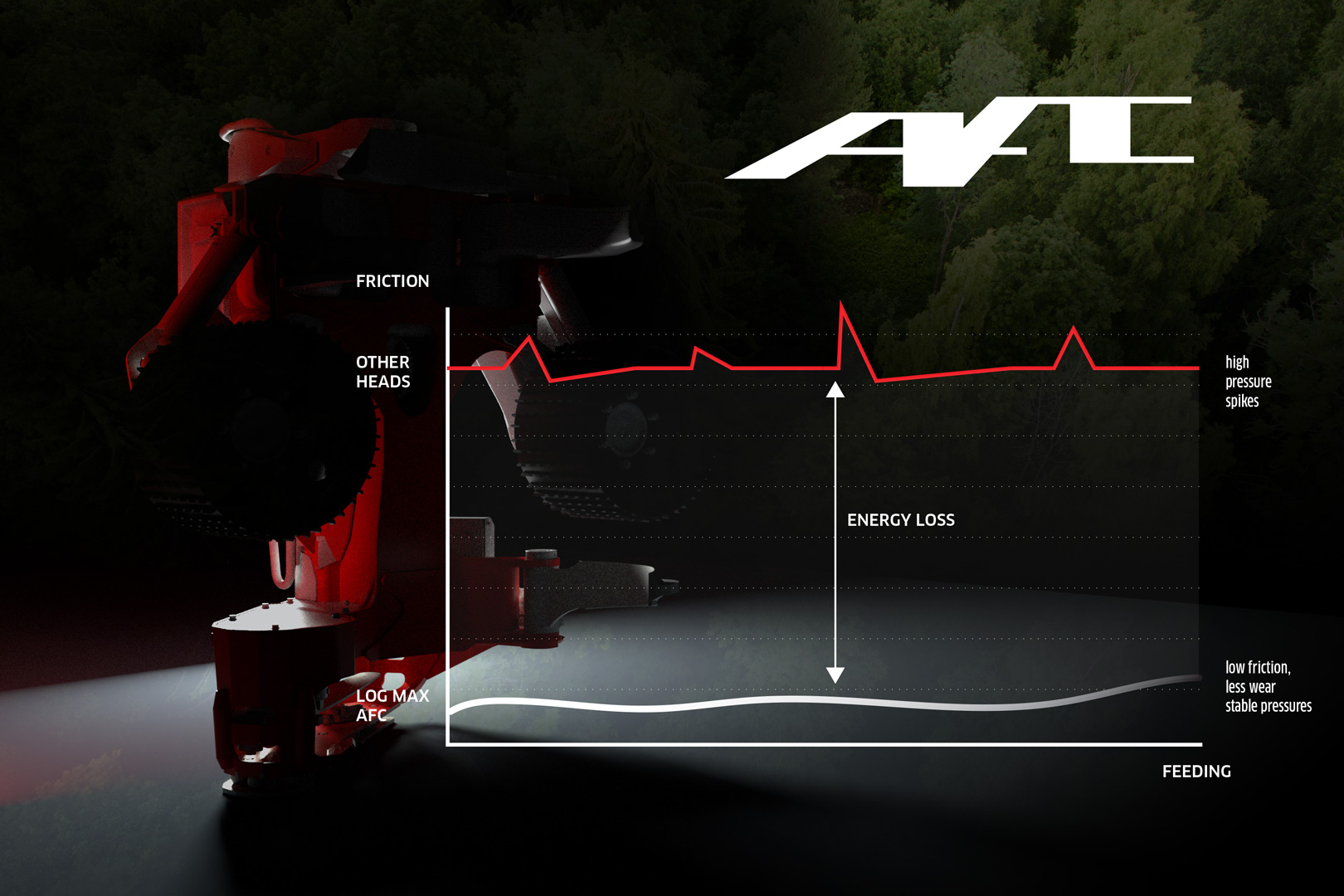

Active Friction Control - AFC

The AFC system is our head’s key technology and allows our heads to harvest trees with high precision and minimal friction.

The goal of the AFC is to minimize the friction between the trunk and the frame, which leads to minimal wear on the unit and lower operating costs because the head doesn't use more power than necessary.

The wood quality will also be high, as neither knives nor feed wheels need to use unnecessary force that damages the wood during processing.

Read more about AFC

Log Mate 510

Log Mate 510 is our control system which is specially developed for Log Max harvester heads and is the absolute best control system for our products.

The control system is robust and compact and of the highest quality. It is Windows-based, which simplifies the administration and updating of the system and provides good support for all new programs and services.

The system uses the latest forest standard StanForD 2010 v2 and v3 and consists of three modules, screen, cabin, and head module.

Read more about Log Mate

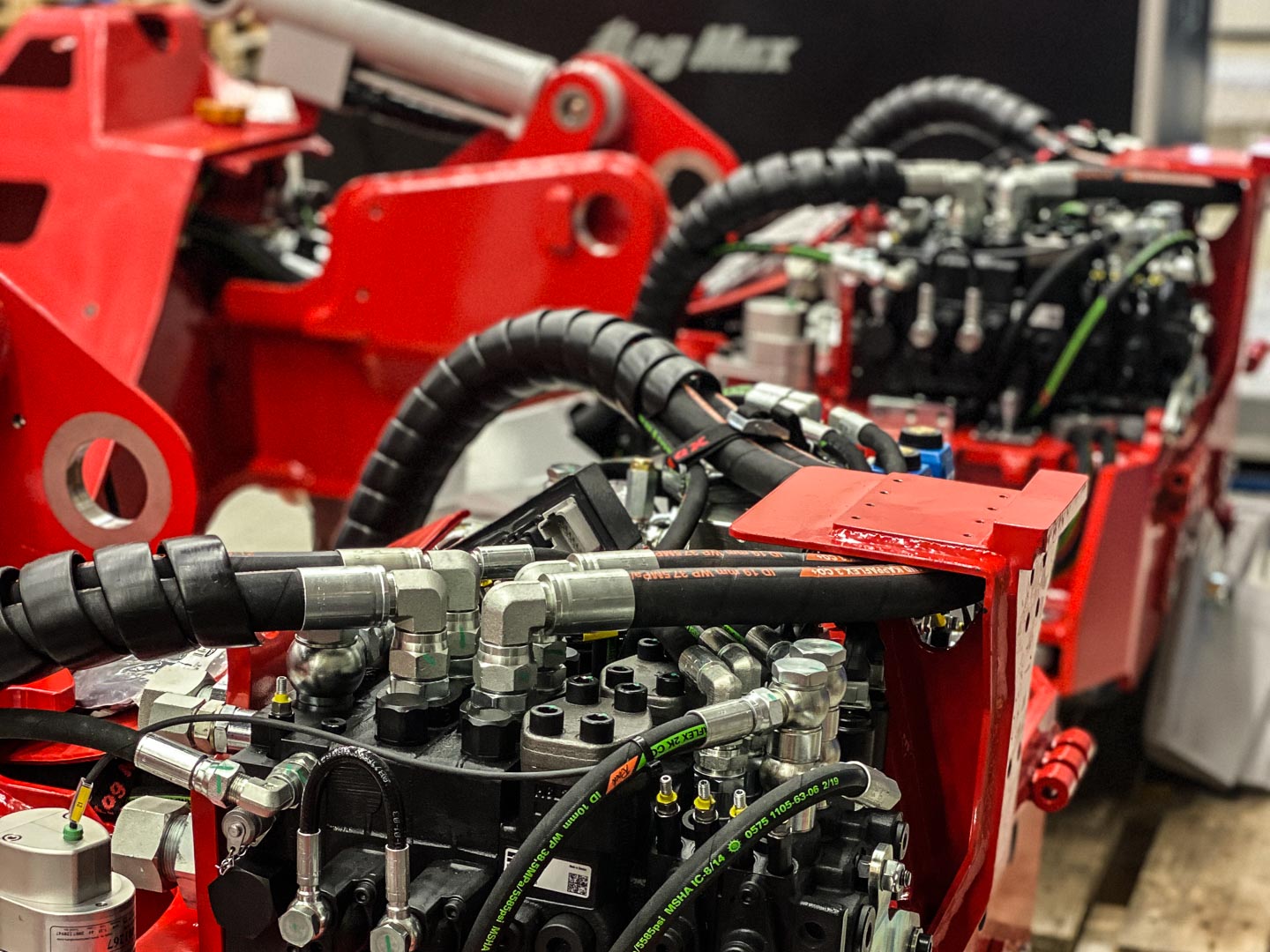

Hydraulics

The hydraulics of our heads are characterized by a simple design. We use a proven technology that we trust and that results in reliable hose management and stable pressures throughout.

Our system has small hydraulic losses, which means that we get the most out of the head's performance.

More about the head design

EQUIPMENT

All optional equipment available for Log Max 7000Twin can be found here

Feed rollers for Log Max 7000Twin

V-STEEL SOFT GRIP

Self-cleaning feed wheels with high traction, both forwards and backwards, without risk of slip damage. The Soft Grip has a slightly lower stud (ca 5 mm) which gives less penetration into the trunk.

V-STEEL HARD GRIP

Self-cleaning feed wheels with high traction, both forwards and backwards, without the risk of spinning. The Hard Grip has a slightly higher stud (ca 10 mm) that provides a better grip around the trunk.

Eucalyptus

Log Max Eucalyptus feed roller is different from our other feed rollers. They are specially designed to debark the thick bark of eucalyptus trees.

Saw units for Log Max 7000Twin

Feed roller motors for Log Max 7000Twin

Variabel 830-1320 cc

Feed force: 41.7 kN

Feed speed: 5.3 m/s / 17.39 ft/s

1147 cc

Feed force: 35.9 kN

Feed speed: 3.9 m/s / 12.80 ft/s

Rotators for Log Max 7000Twin

Indexator AV17S

The rotator has low weight and high performance. This is the perfect rotator for heavy lifting and hard work.

- 160 kN lifting capacity

- Robust and construction

- High torque

Indexator H182

Durable, powerful, and with the highest performance.

- 160 kN lifting capacity

- Optimized productivity and efficiency when combined with MPB swing dampers

- High torque and precise

SOMETHING EXTRA

Selectable optional equipment for Log Max 7000Twin

Processing knives

The processor knives have protruding tips that ease the prehension of logs from a pile of already felled trees. The processor knives are available in two designs, a welded and a cast one. They are equally durable but the welded one has replaceable knives edges, it also weighs slightly more.

Field repair kit

A spare parts kit with the most vital components to minimize downtime. Contains sensors, cylinders etc. The kit varies (content and price) depending on the head model and equipment.

Please contact us for more information.

Sawdust deflector

To minimize sawdust clouds when processing a log and also the risk of chain shots, a sawdust deflector is mounted on the saw box.

Hose Kit

Kit with replacement hose.

Ask your local dealer for more information.

Color marking

Includes tanks and equipment for two different colors. Color marking blocks are mounted in the saw box.

Find End sensor - laser

Used to easily find the root end / zero point of a log. The Find End sensor consists of a laser that is mounted in the saw box. This allows to easily

zero-reset without having to use the saw. This function optimizes and facilitates work when processing from the pile.

Stump treatment

Prepares the head for stump treatment. Requires a separate pump on the carrier.

Rotator control

To reduce weight and cost, it is possible to choose the rotator control option, which means that the rotator is controlled from the head instead of from the carrier.

The advantages are that it frees weight on the carrier by eliminating between 20-30 m of hose and also reduces costs. If the option is chosen, an extra valve is mounted to the head.

SUPPORT

Here you will find important information, links and contacts for the best support for your Log Max head.