HEAD DESIGN

The philosophy behind our reliable heads as well as their functionality

SIMPLICITY

Our heads are characterised by their simplicity.

We believe in avoiding unnecessary complications.

Simple tends to be durable and, as a consequence, reliable.

Reliability offers savings in both time and money.

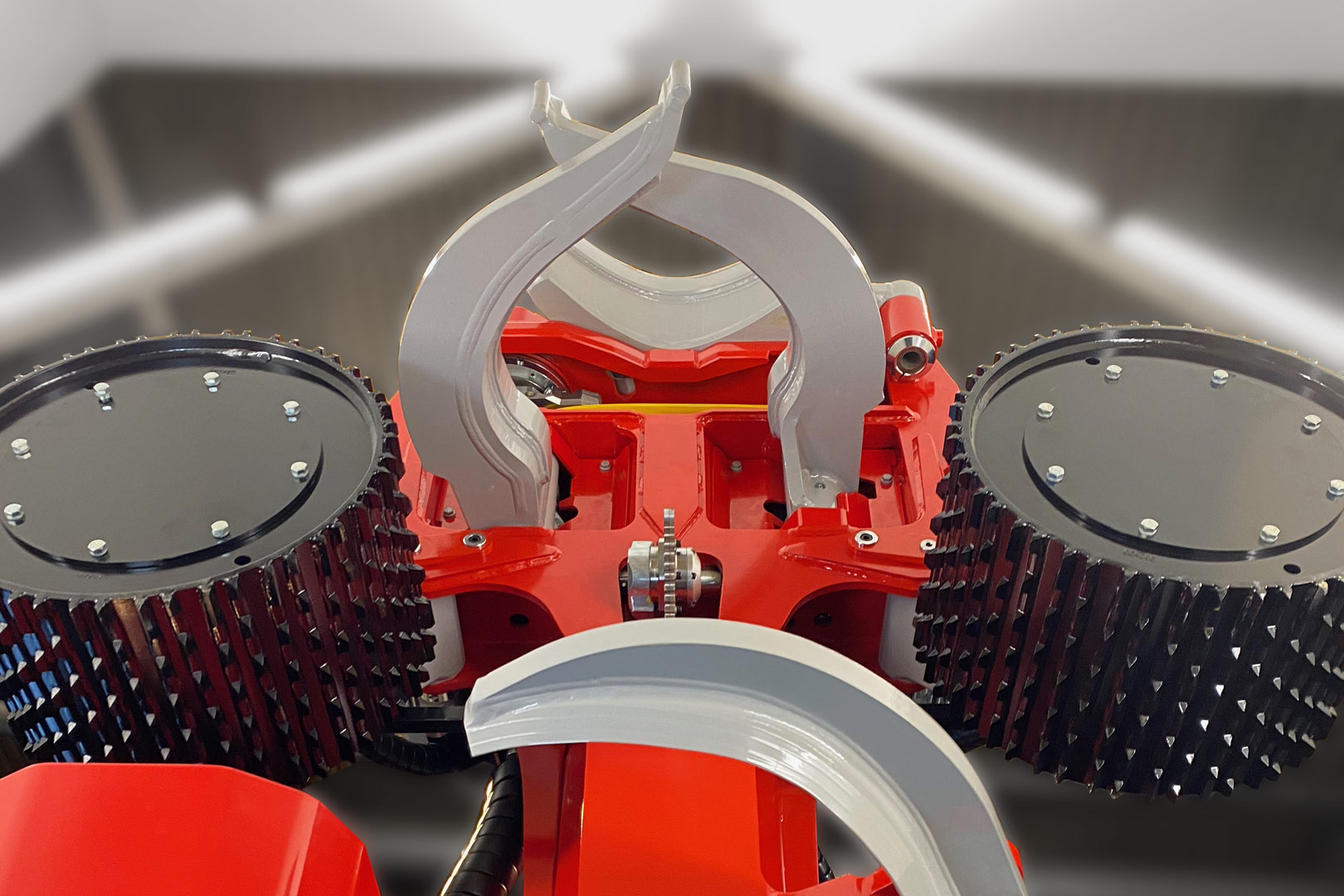

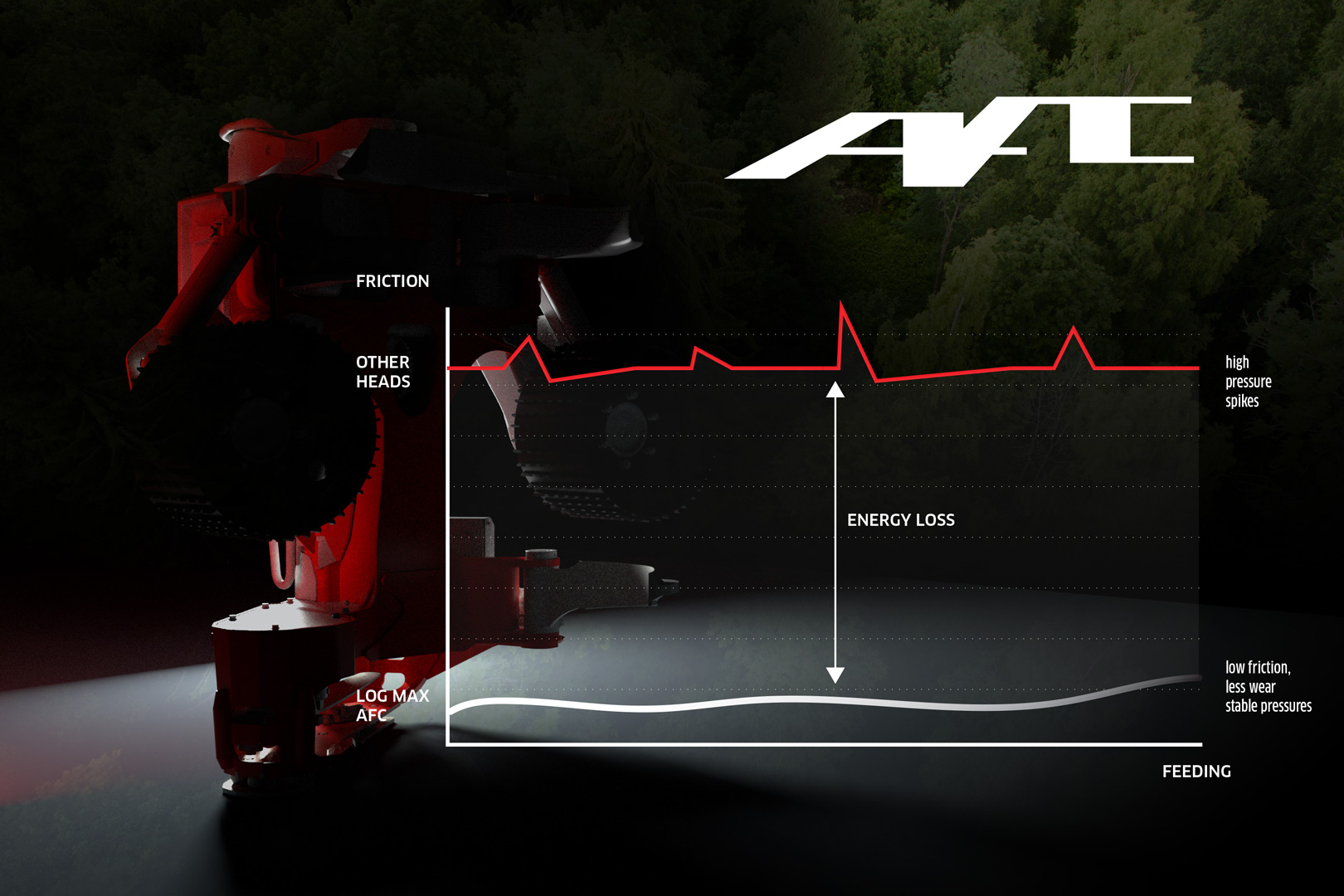

MINIMAL FRICTION

Log Max harvester heads stand out much due to their unique patented Active Friction Control™ (AFC) system, which determines how the head handles the stem.

As the name suggests, this function gives the head full control over how the stem is fed so as to reduce friction.

This offers many advantages:

- Less wear

- Better fuel economy

- Greater durability

- Higher resale value

- No unnecessary timber damage

MINIMAL FRICTION

AFC is the cornerstone that enables our heads to be operated with precision and minimal friction rather than force and brute strength.

The aim is for the stem to pass through the head as smoothly as possible while ensuring optimal delimbing.

The AFC function ensures that the stem is never pressed up against the frame, instead gliding smoothly through the feed.

You can read more about AFC here

FRAME DESIGN

The frame lays the foundation for the entire head's functionality and durability

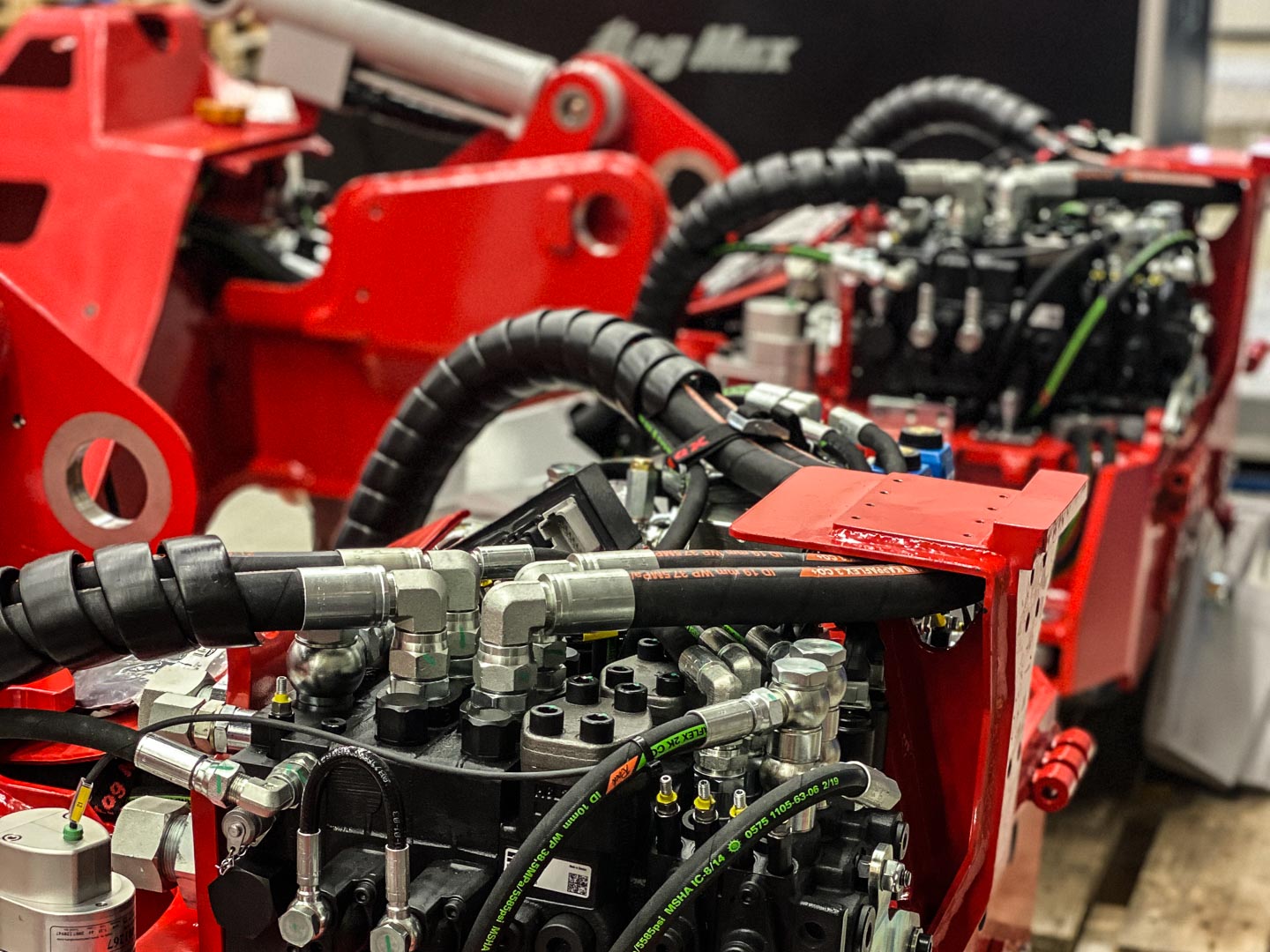

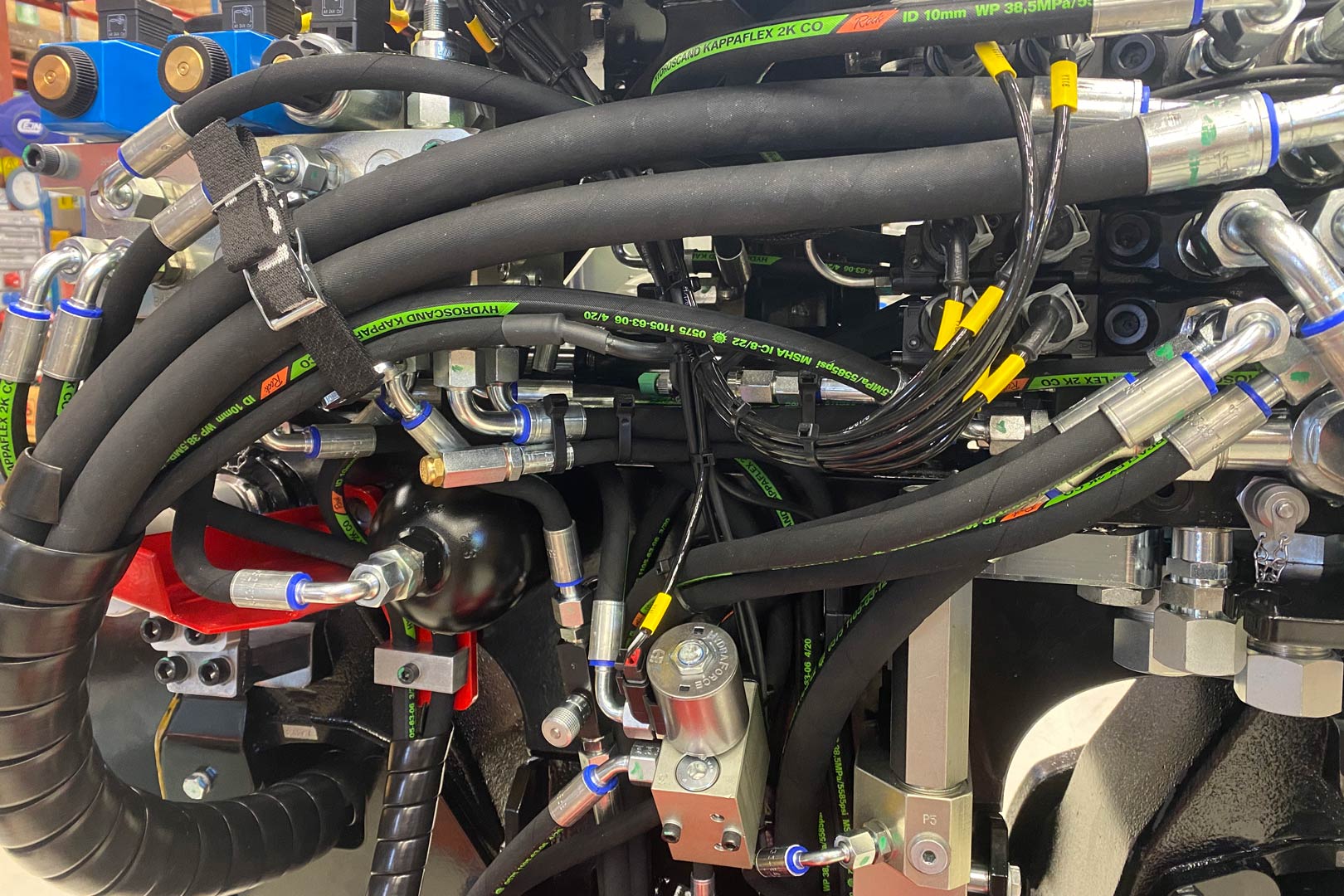

SHORT HOSE ROUTES

Our patented AFC system enables us to construct our heads differently to our competitors.

It enables us to minimise the complexity of the head design. As an example, our heads are designed to use short hydraulic routes. This minimises pressure drops and pressure spikes and shortens flows. It also minimises hose movements, which means that our hoses have a longer service life.

On average, our heads use no more than 20 hoses for 8,000 hours of operation.

FIRST-CLASS COMPONENTS

All of our suppliers are carefully selected to ensure that we can deliver products of the highest quality. When selecting suppliers for hydraulic components, such as hoses, we make no exceptions.

We only use hydraulic hoses of the highest quality and include a generous margin when choosing the pressure rating. All hoses are cut, crimped and checked at our factory.

High-quality hydraulic hoses ensure fewer hose failures and less leakage, which in turn result in less environmental impact and more savings.

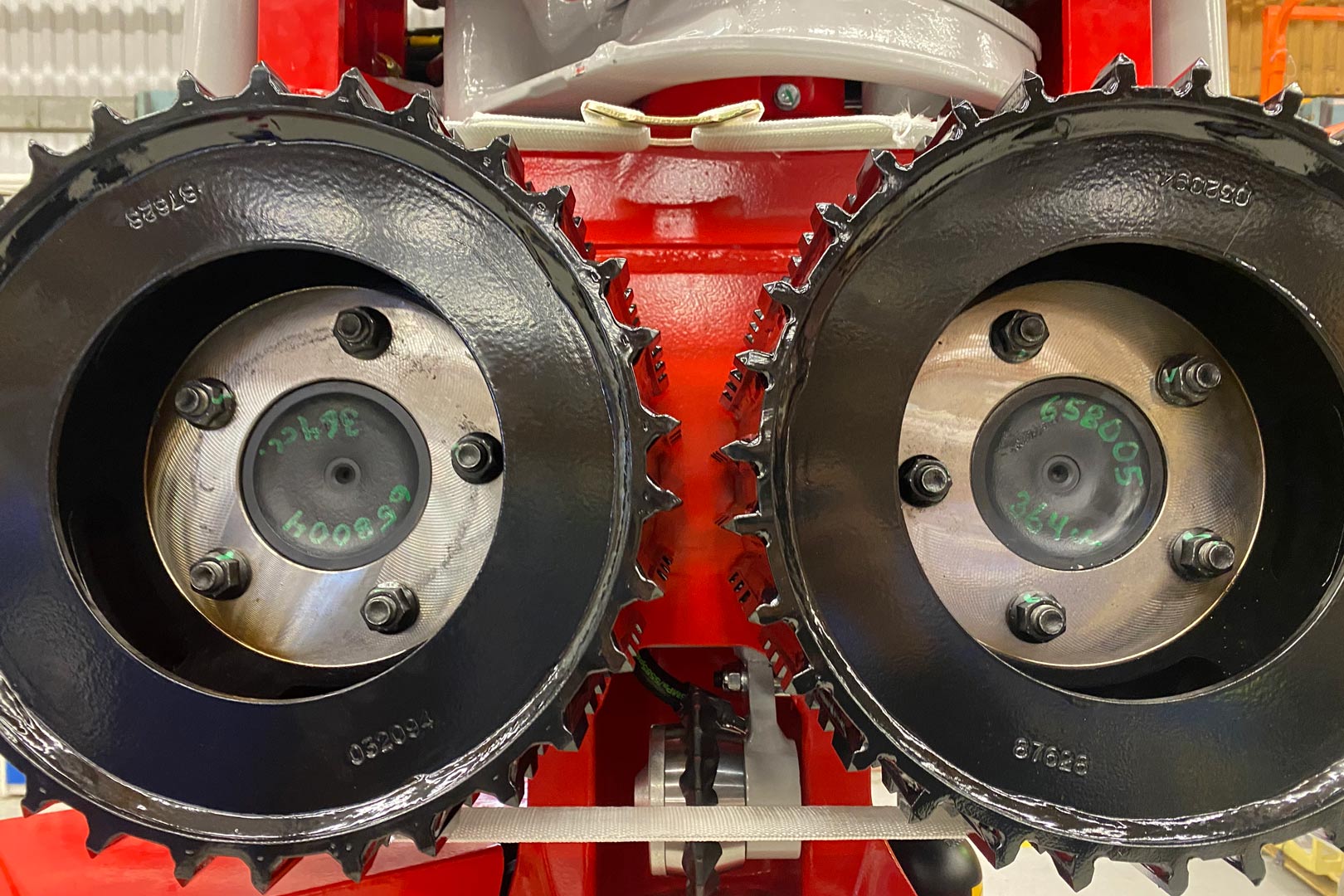

STRAIGHT FEED ROLLER ANGLES

Nor do we need angled feed rollers to hold the stem against the frame through the feed, which has its advantages:

- The hoses for the feed roller arms can be kept shorter

- Less movement and less wear

- Improved timber quality as the stem is subjected to less force and friction

- Advantageous in multi-tree handling as the angle creates the right conditions for all stems to come into contact with the feed rollers

FOUR-POINT MEASUREMENT

Since the feed rollers are straight rather than angled, we can offer our customers four-point measurement. This enables our heads to provide more accurate volume calculations and better bucking.

Measurements are made using four points: two opposite each other in the feed rollers, one in the lower delimbing knife, which consists of a sensor, and a baseline in the frame. This enables the system to present extremely good measurement results based on four measurement points.

Read more here

MATERIALS

We strive to make our heads sustainable for users and the climate

SWEDISH STEEL

The steel industry in the region where Log Max is headquartered has a long history.

The Swedish steelmaker SSAB was founded just a few kilometres from our head office. This means that the region has strong traditions, a plentiful supply and a great deal of knowledge when it comes to steel.

Log Max heads are mostly made of steel from SSAB.

Visit SSAB's website

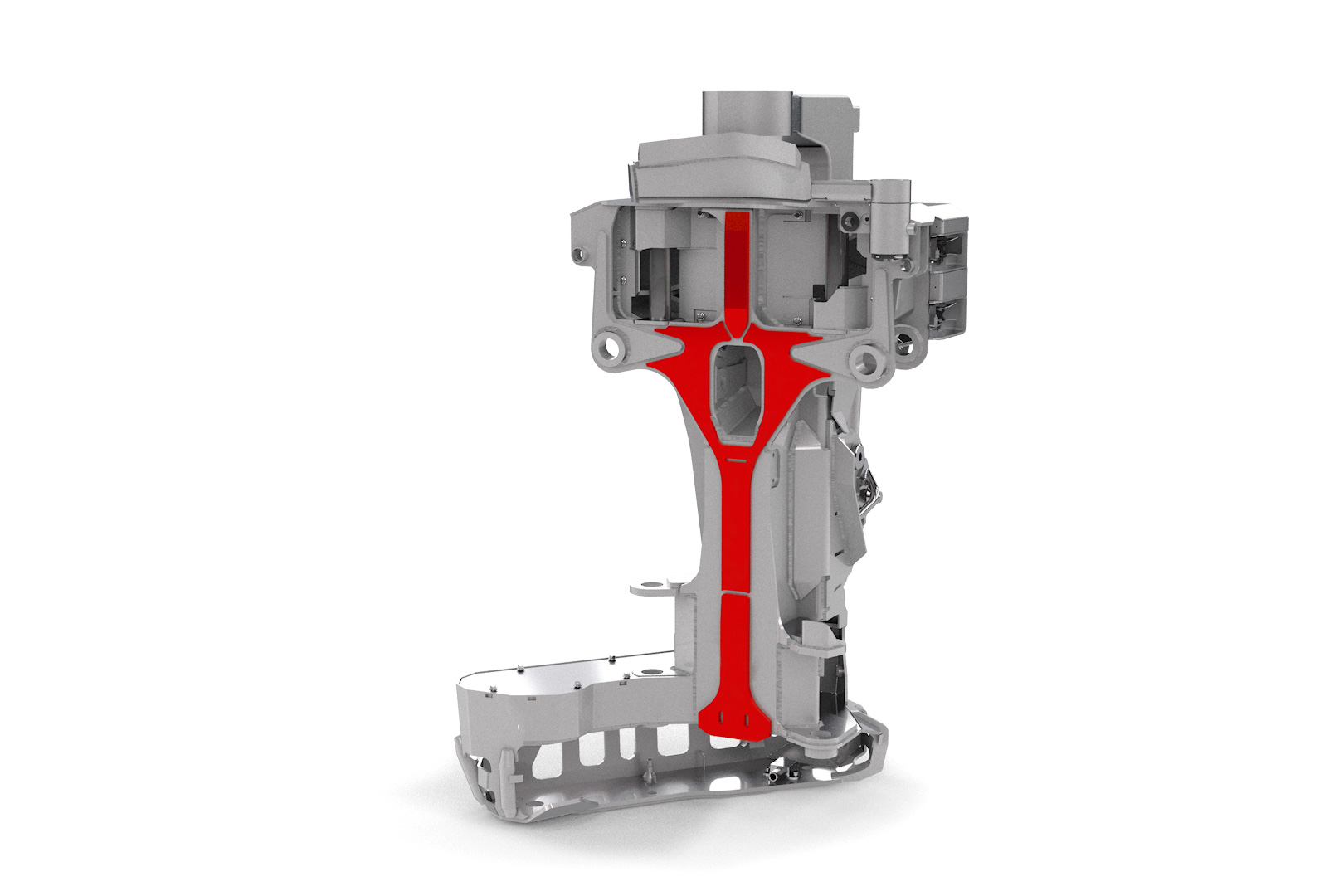

THE FRAME

The head frames are made of Strenx, a high-strength, high-performance steel from SSAB.

The reason for using Strenx is to have the strongest, most durable steel possible while keeping the weight low.

Strength and weight are both important considerations when building the heads, which is why we chose Strenx.

WEAR PLATES

The wear plates used on the head are made of the world's foremost wear-resistant steel, Hardox, which is produced by SSAB.

Extra wear plates are fitted to the parts of the head that are subjected to the most wear.

The steel used for the wear plates, Hardox, is hard throughout, from the surface to the core, extending the service life of the head.

CAST STEEL

We choose to cast our delimbing knives and certain felling links because cast steel is superior in terms of strength and toughness in all directions.

Casting is also the preferred method for creating complex shapes, making efficient use of the material and ensuring the same outcome every time.

Our products are cast by Keycast

BUSHINGS

The standard bushings found in the shafts on a Log Max head are made of bronze. Bronze has innate lubricating properties, which is an advantage when metal is sliding against metal.

Some bronze bushings are replaced with steel bushings for greater wear resistance. As an example, the E6, which is designed for harvesting eucalyptus, is fitted with steel bushings because these heads come into contact with a great deal of sand found in and under the bark of eucalyptus trees. Steel bushings can handle more wear and higher loads than bronze bushings.