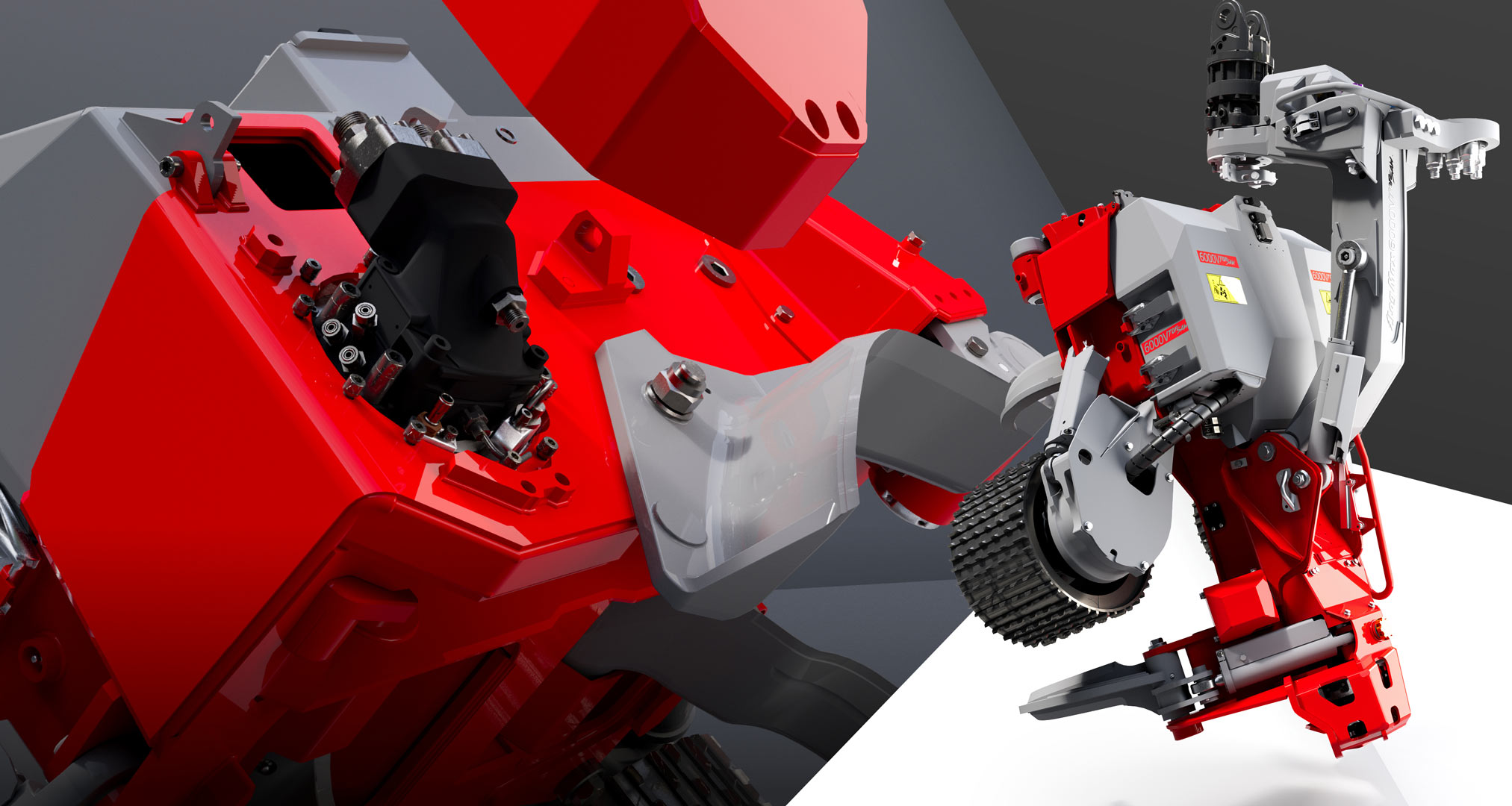

Log Max 6000V Top Saw is well-suited for both wheeled and tracked harvesters. With the Top Saw, you can maximize the timber yield from every log, and the new function, Tilt Control, enables you to place the head at any desired tilt angle. 6000V Top Saw will be available on the market during Q1 2026.

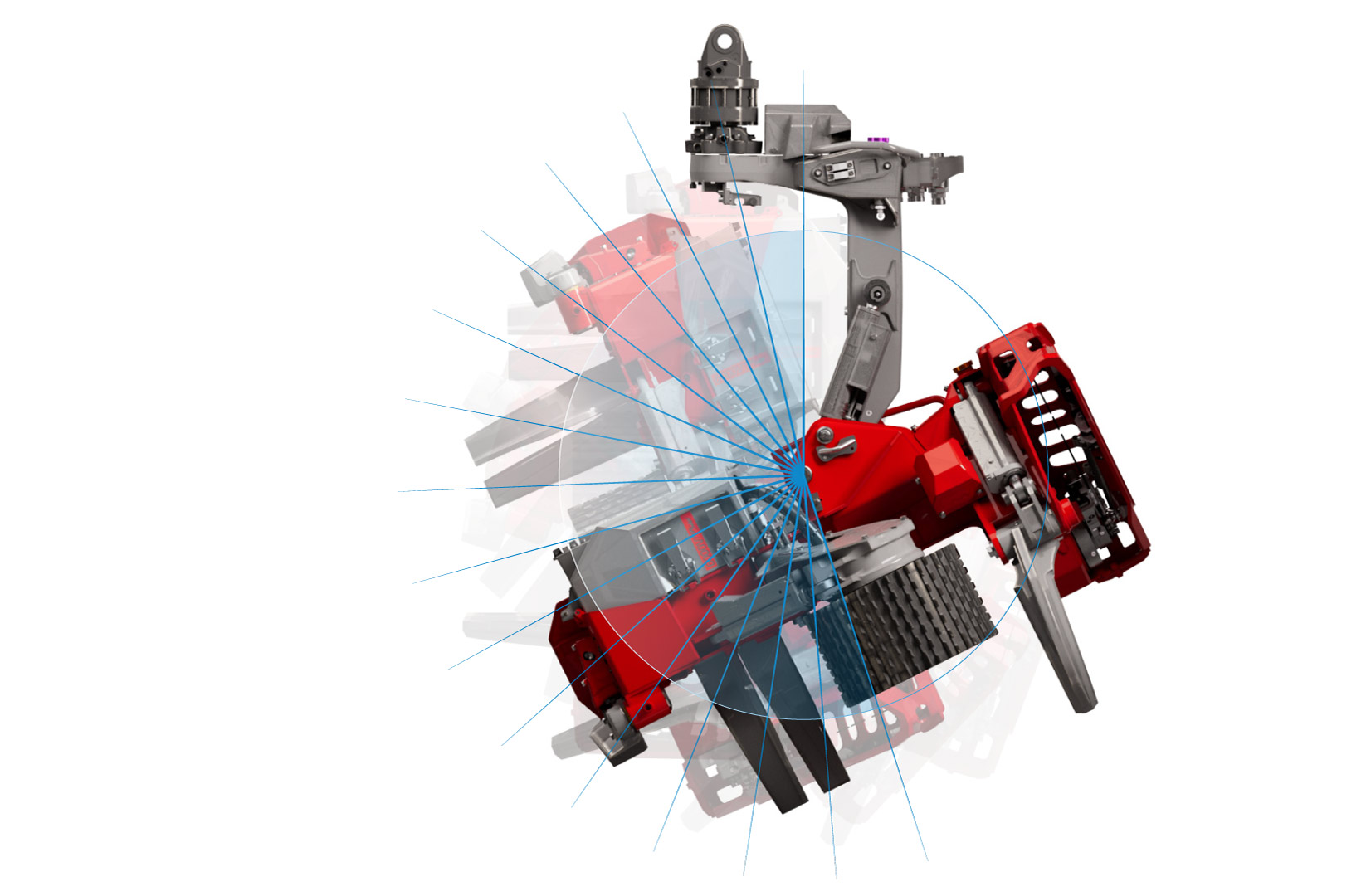

TILT CONTROL

The new Tilt Control system enables you to place the head at any desired tilt angle.

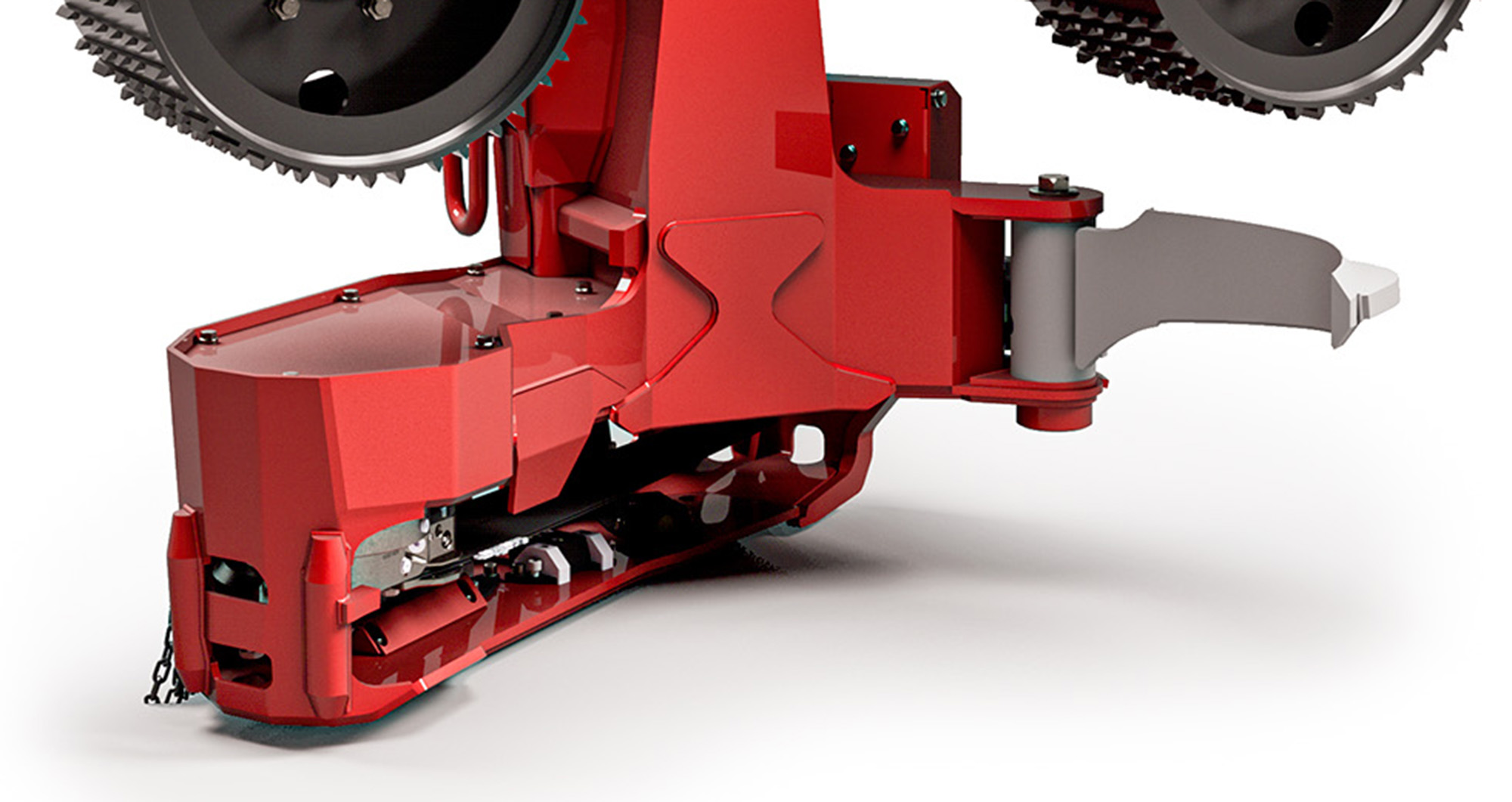

OPTIMIZED SAW BOX

The saw box has been redesigned and extended to accommodate saw bars up to 90 cm in length.

ACCURATE AND PRECISE MEASUREMENT

We have updated the length measurement function to get the best measurement result.

Weight

1608 KG

Highest productivity

14 - 44 CM

Between feed rollers

1.7 - 62.5 CM

Max cutting diameter

78.4 CM

Assets diameter

47 CM

FEATURES

What makes Log Max 6000V Top Saw your best choice

Tilt Control

The new Tilt Control system enables you to place the head at any desired tilt angle. Tilt Control comes as standard and the valve for this function is mounted below the existing tilt valve on the left block.

Tilt Control is a game changer when processing heavily limbed trees or when working in steep terrain.

OPTIMIZED GEOMETRY AND DESIGN OF THE SAW BOX

The saw box has been redesigned and extended to accommodate saw bars up to 90 cm in length, a new root protection plate providing enhanced protection to the chain against roots and enables easier cutting of larger trees with a maximum diameter of 78,4 cm (30.9”).

Furthermore, the footprint of the saw box has been reduced, making it particularly advantageous in snowy conditions.

OUTSTANDING LENGTH MEASUREMENT

The length measurement function has been significantly improved to enhance accuracy. Changes include redesigning the measure wheel cylinder, updating the hydraulic circuit, reinforcing the measuring wheel arm and attachment, the measuring wheel is larger in diameter. These enhancements allow the measuring wheel to precisely follow the stem’s contour, resulting in superior measurement results.

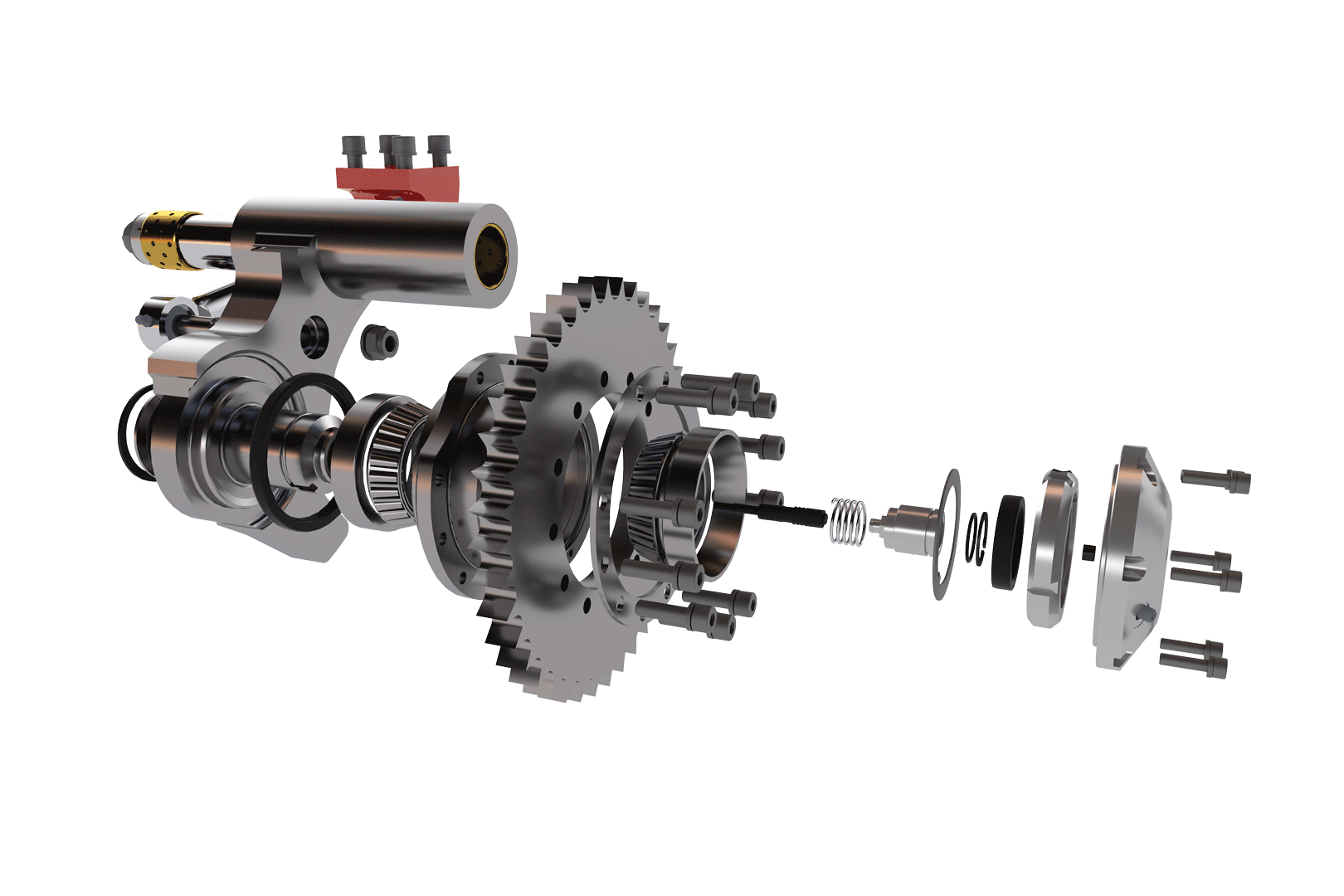

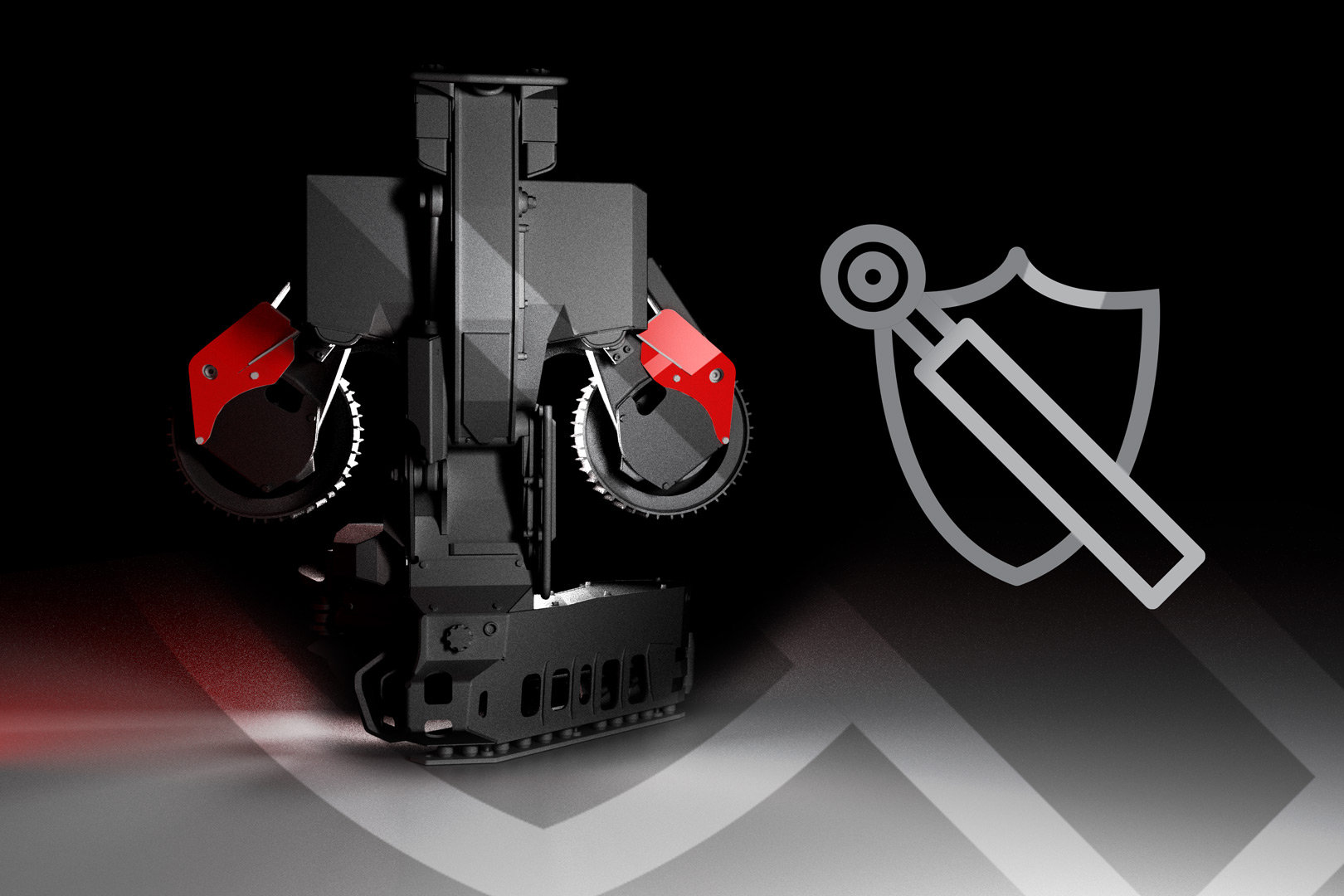

An impressive saw unit

The Log Max 6000V Top Saw is equiped with two 318 MK2 with 30cc motors. Through meticulous material selection and innovative design concepts, these units significantly reduces maintenance requirements while maximizing durability. New grease nipples have been added to the front sides, enabling easy application of grease to safeguard against moisture, dirt, and debris.

The saw bar bracket has undergone significant improvements. It now includes a protective cover and rubber seals to seal off the bracket, preventing the infiltration of dirt and dust. The saw bar holder has been upgraded with premium-grade Hardox 450 material and an improved design. The attachment mechanism for the saw bar itself has been reinforced, ensuring enhanced strength and longevity.

Read more about saw units

Lubrication points

In order for all lubrication to be done when the head is in the tilted position, the head has accessible lubrication points. The lubrication points are brought forward on the saw box so that they are easy to get at. It increases safety, facilitates maintenance work, and shortens downtime.

Safety pin

To simplify service, facilitate transport and increase safety, a "Safety Pin" has replaced the safety chain, which forms a locking mechanism between the frame and the felling link. You can now link a bracket under the rotator to a stand in the frame with the help of a locking pin.

Rotator control

To reduce cost, it is possible to choose the rotator control option, which means that the rotator is controlled from the head instead of from the base machine.

The advantages are that it frees weight on the base machine by eliminating between 20-30 m of hose and also reduces costs. If the option is chosen, an extra valve is mounted to the head.

Reinforced frame

To increase durability and reduce the risk of cracks in the frame, we have created a reinforced attachment for the upper delimbing knife. The frame is reinforced at the mainline, where the upper delimbing knife slides on the frame to increase durability and extend its life span.

TECHNOLOGY

Unique technologies for your Log Max head

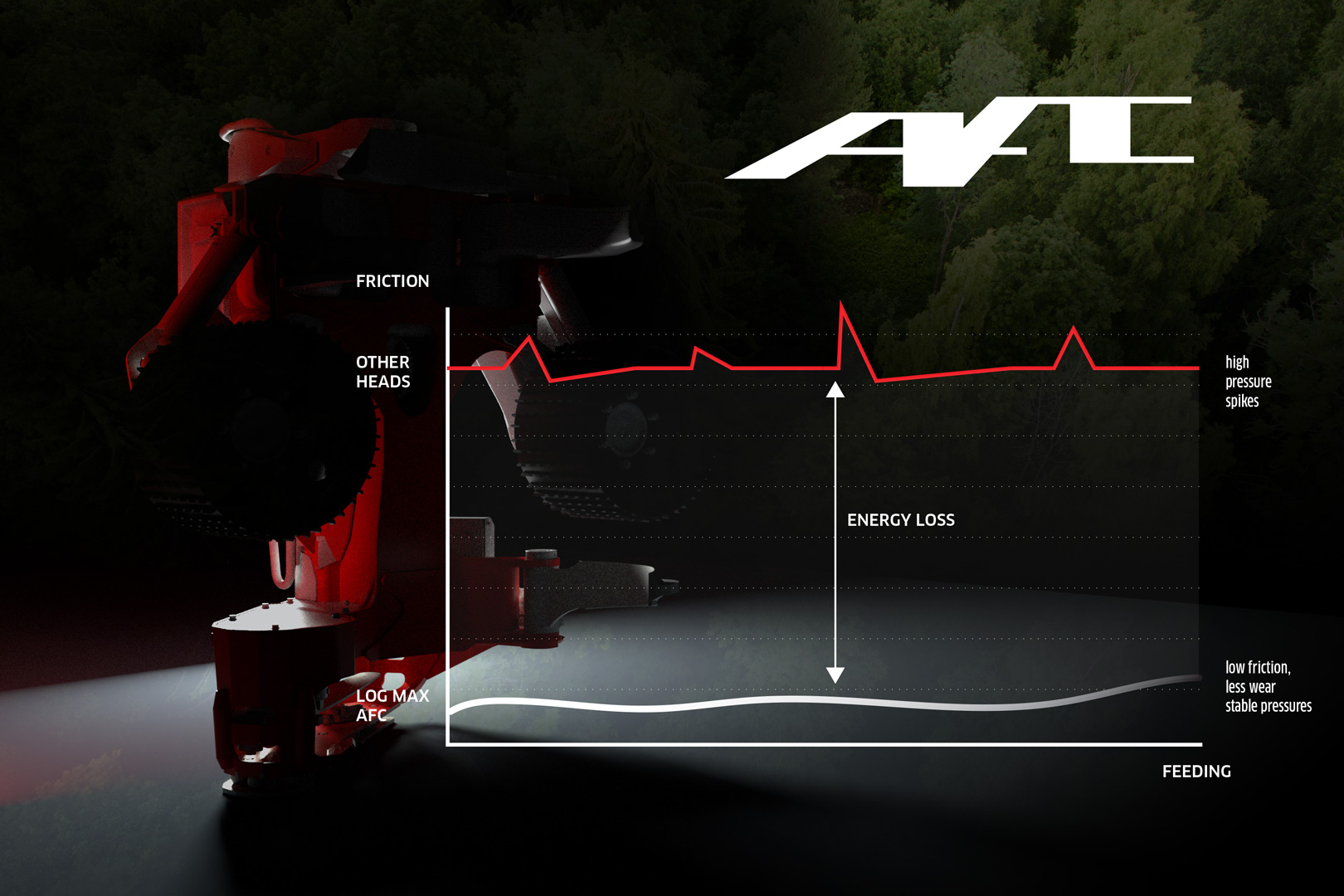

Active Friction Control - AFC

The AFC system is our heads' key technology and allows our heads to harvest trees with high precision and minimal friction.

The goal of the AFC is to minimize the friction between the trunk and the frame, which leads to minimal wear on the unit and lower operating costs because the head doesn't use more power than necessary.

The wood quality will also be high, as neither knives nor feed wheels need to use unnecessary force that damages the wood during processing.

Learn more about AFC

Log Mate 510

Log Mate 510 is our control system which is specially developed for Log Max harvester heads and is the absolute best control system for our products.

The control system is robust and compact and of the highest quality.

It is Windows-based, which simplifies the administration and updating of the system and provides good support for all new programs and services. The system uses the latest forest standard StanForD 2010 v2 and v3 and consists of three modules, screen, cabin, and head module.

Learn more about Log Mate

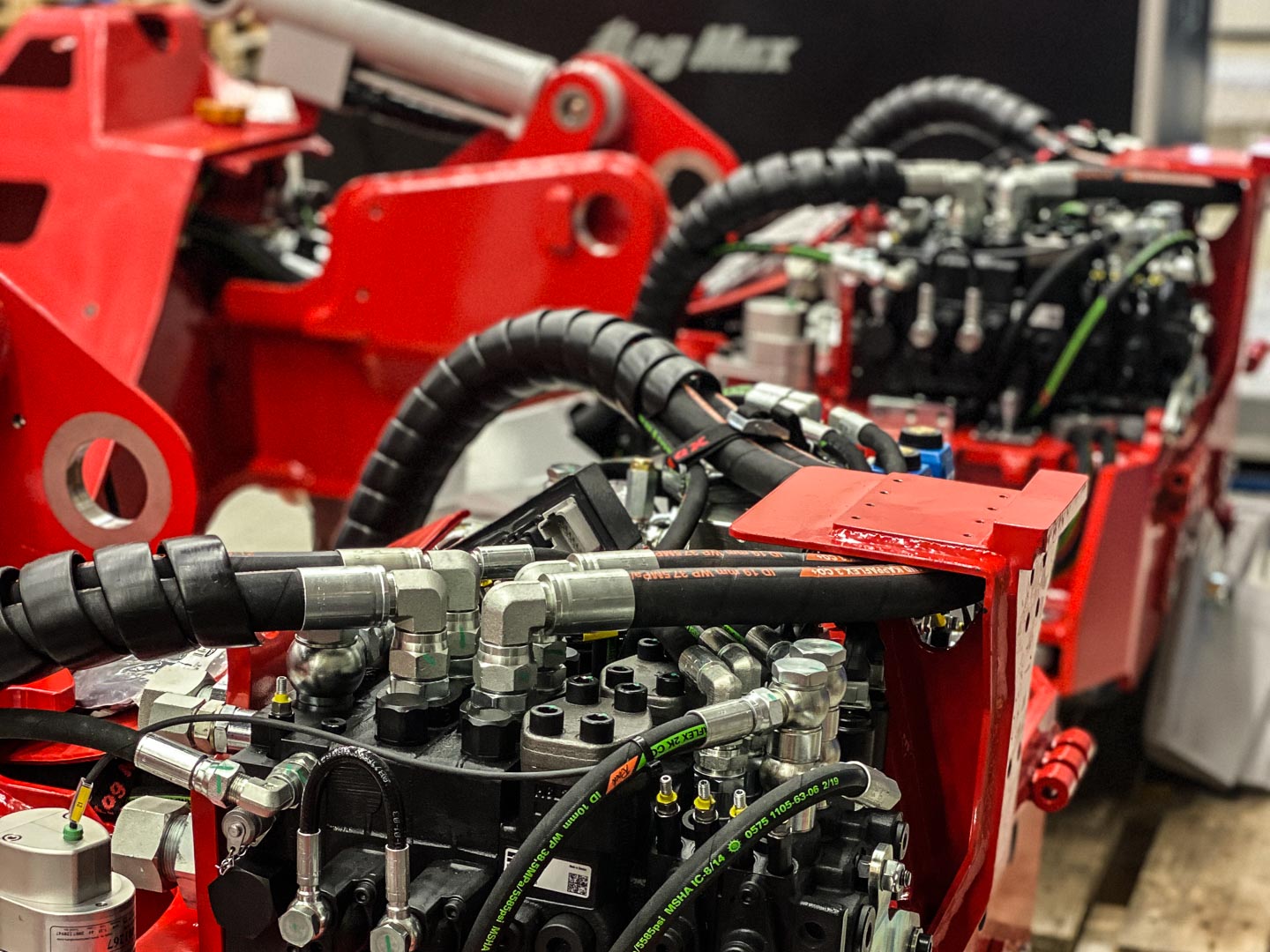

Hydraulics

The hydraulics of our heads are characterized by a simple design. We use a proven technology that we trust and that results in reliable hose management and stable pressures throughout.

Our system has small hydraulic losses, which means that we get the most out of the head's performance.

More about the head design

Feed rollers

To optimize the head's function, you need to choose the feed rollers that fit both your head, but also the type of forest that you work in the most. Our feed rollers always work perpendicular to the tree, in contrast to many other units that have angled feed rollers. Having a straight feed roller leads above all to reduced friction losses but also to minimal penetration into the trunk.

EQUIPMENT

All optional equipment available for Log Max 6000V Top Saw can be found here

Feed rollers for Log Max 6000V Top Saw

V-STEEL SOFT GRIP

Self-cleaning feed wheels with high traction, both forwards and backwards, without risk of slip damage. The Soft Grip has a slightly lower stud (ca 5 mm) which gives less penetration into the trunk.

V-STEEL HARD GRIP

Self-cleaning feed wheels with high traction, both forwards and backwards, without the risk of spinning. The Hard Grip has a slightly higher stud (ca 10 mm) that provides a better grip around the trunk.

Eucalyptus

Log Max Eucalyptus feed roller is different from our other feed rollers. They are specially designed to debark the thick bark of eucalyptus trees.

Feed roller motors for Log Max 6000V Top Saw

Poclain MS08 - 857 cc

Feed force: 28.7 kN

Feed speed: 5.0 m/s / 16.40 ft/s

Poclain MS08 - 780 cc

Feed force: 26.1 kN

Feed speed: 5.5 m/s / 18.04 ft/s

Saw units for Log Max 6000V Top Saw

True-Cut 318 - 19cc

The True-cut saw units have a built-in saw valve that detects the motor speed and adjusts the saw bar feed rate according to the speed. This function allows True-cut to maintain a constant chain speed of 40 m/s throughout the cutting, regardless of the tree size or species.

Tensioner: Automatic

Saw Motor: 19 cc / 1.16 cu in

Saw Chain: 0.404"

Saw 318 - 30cc

The saw 318 auto-releases the chain tensioner's pressure when you turn off the base machine, so you do not need any tools to change the chain.

Tensioner: Automatic

Saw Motor: 30 cc / 1.83 cu in

Saw Chain: 0.404"

Top Saw- Saw 318 - 30cc

The saw 318 auto-releases the chain tensioner's pressure when you turn off the base machine, so you do not need any tools to change the chain.

Tensioner: Automatic

Saw Motor: 30 cc / 1.83 cu in

Saw Chain: 0.404"

Rotators for Log Max 6000V Top Saw

Indexator AV17S

The rotator has low weight and high performance. This is the perfect rotator for heavy lifting and hard work.

- 160 kN lifting capacity

- Robust and construction

- High torque

Indexator H182

Durable, powerful, and with the highest performance.

- 160 kN lifting capacity

- Optimized productivity and efficiency when combined with MPB swing dampers

- High torque and precise

Indexator HX 35 LS

Low-profile HX is loaded with a number of advantages where the machine, driver, and unit work efficiently - quickly and smoothly.

- 160 kN lifting capacity

- Upper interface MPB2 184 mm

- Lower interface Ø 173 mm

SOMETHING EXTRA

Selectable optional equipment for Log Max 6000V Top Saw

Color marking

Includes tanks and equipment for two different colors. Color marking blocks are mounted in the saw box.

Find End sensor - laser

Used to easily find the root end / zero point of a log. The Find End sensor consists of a laser that is mounted in the saw box. This allows to easily

zero-reset without having to use the saw. This function optimizes and facilitates work when processing from the pile.

Reinforced covers for the feed roller arms

Reinforced covers for the feed roller arms with integrated cylinder rod protection.

Hose holder

A hose holder on the felling link is available as option when choosing the reinforced felling link.

SUPPORT

Here you will find important information, links and contacts for the best support for your Log Max head.

Service

Serviceability is one of the most important factors affecting productivity.

Get help here

Guarantee

We are a reliable partner with extensive guarantees and generous warranty claims.

Read more here

Technical Training

Is your Log Max head correctly set, so you maximize the head's function?

Read more here

Documentation

Product information is available for all Log Max units. We also have other help documents to download.

Go to downloads